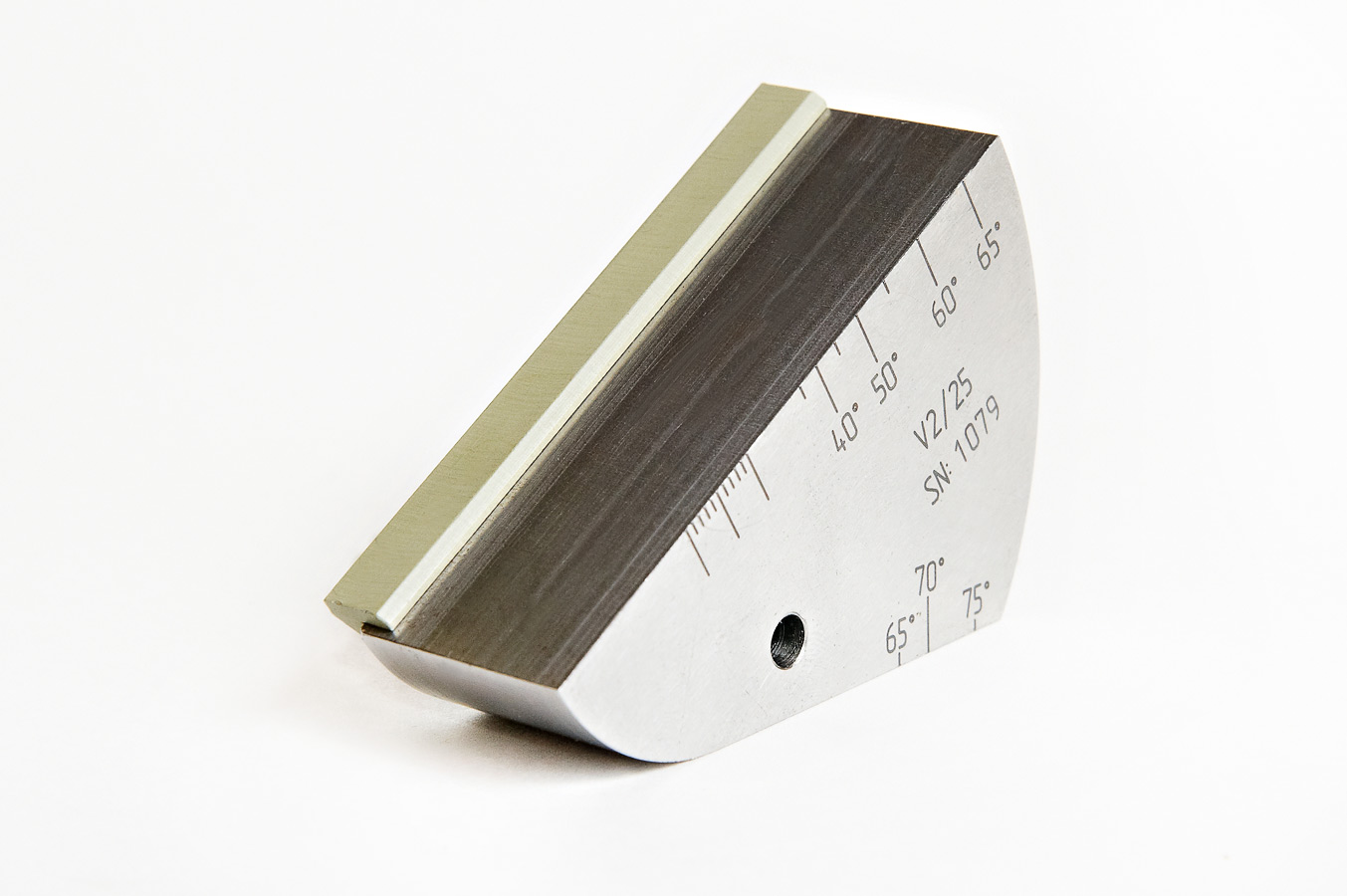

T-square Rels V2

The RELS V2 T-square provides straight trajectory of ultrasonic transducers movement on a ultrasonic V2 calibration block.

T-square provides perpendicularity of a trajectory of movement to the hole of V2 calibration block.

The T-square effectively increases the speed and accuracy of determining the following parameters:

- Entry point of П121 transducer

- Arrow of П121 transducer

- The delay in the prism of П121 transducer

- Setting the levels of sensitivity of the flaw detector

- Setting the depth gauge of the flaw detector

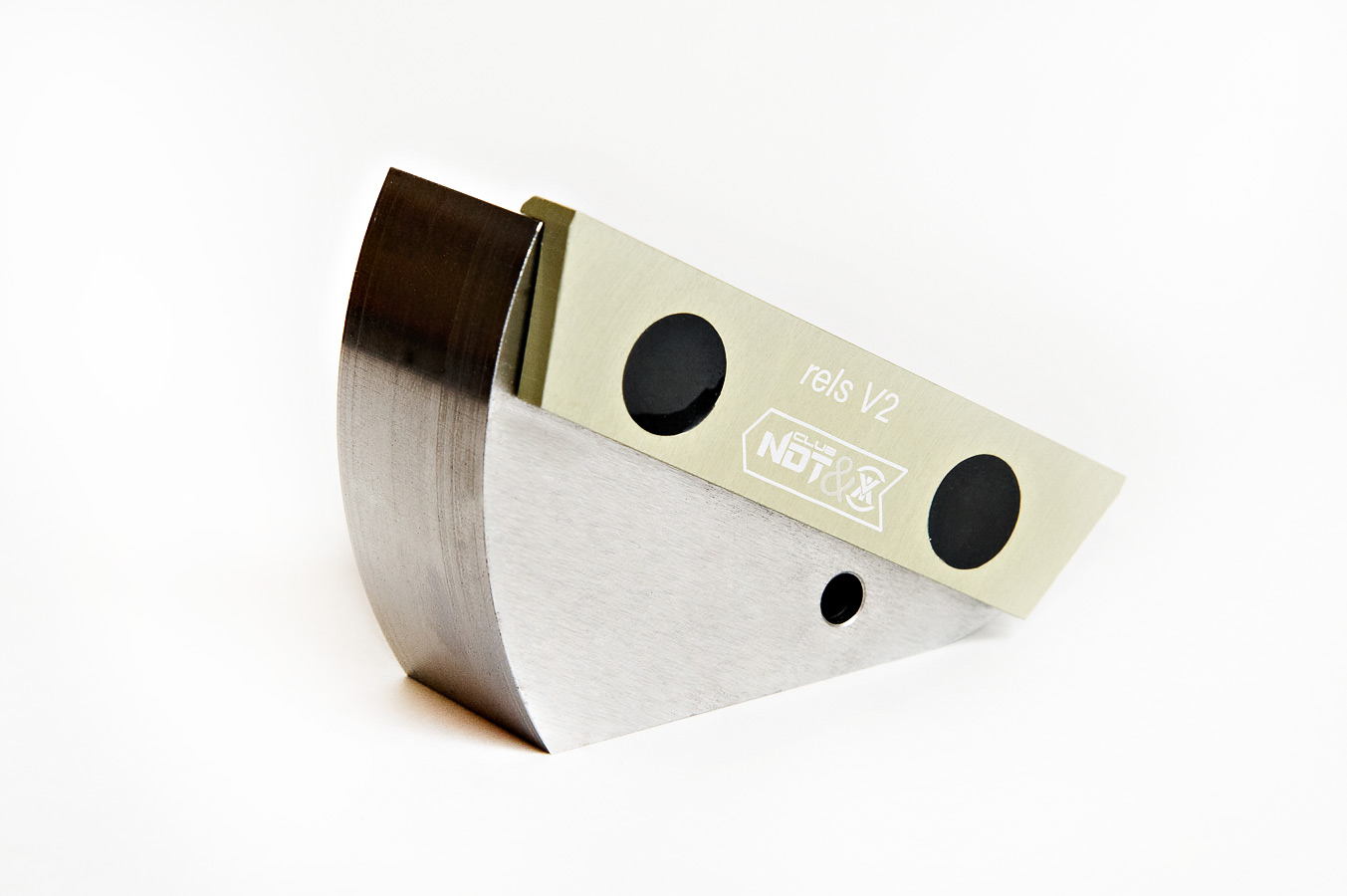

| Material | Aluminium alloy | |

| Overall dimensions (L×W×h) | mm | 74×17×8 |

| Weight | gr | 15 ± 2 |

| Protective and decorative coating | Colored anodic oxidation | |

| Scale | Not available | |

| Built-in magnets | Available | |

| Setting dimensions | mm | 74×15×3.5 |

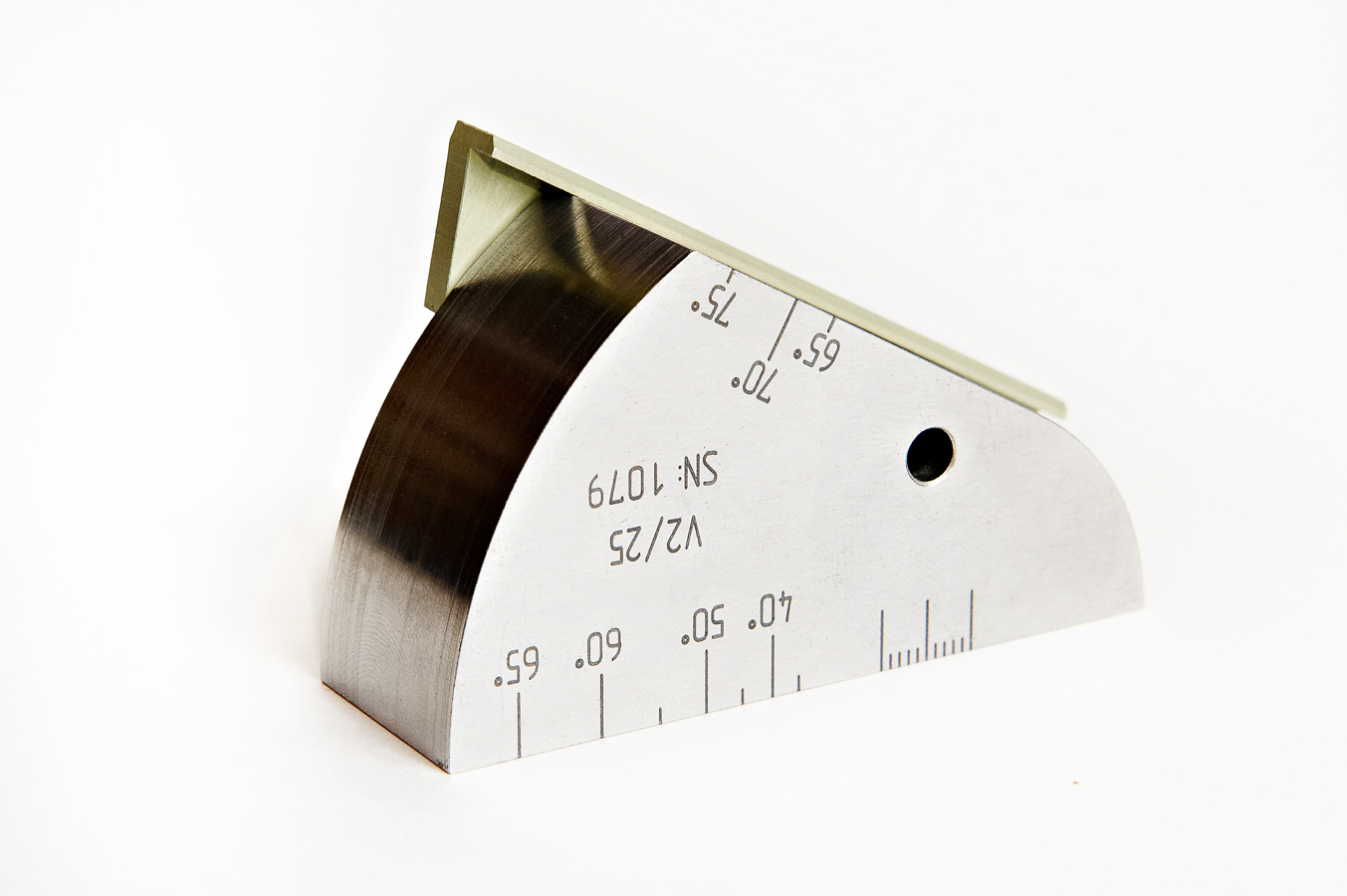

| Active work surface of V2 calibration block with fixed T-square | mm | 75×21.5 (for V2 width 25mm) 75×16.5 (for V2 width 20mm) 75×9 (for V2 width 12,5mm) |

| The force of magnetic pressing | kg | 0.2 |

| Directing brink of a straight path | Inclined at an angle of 45° |

NOTE

Geometry of T-square in combination with built in magnets and anti-slip pads fixes its position on the V2 calibration block.

The T-square is intended for installation on both the main flat working surface 0° 40° 50° 60° 65°of V2 calibration block, and the second flat working surface 65°70°75°.

The T-square effectively eliminates false maximum signal from the angle between the hole and side brink of the calibration block.

Inclined directing brink minimizes the friction of the transducer, improves the smoothness of movement, optically doesn’t close the entry point on the transducer.

T-square, in principle, does not fix the position of the transducer. It additionally allows you to quickly and clearly identify the azimuthal deflection of the beam by rotating the transducer, while maintaining a straight path of movement on V2 calibration block.